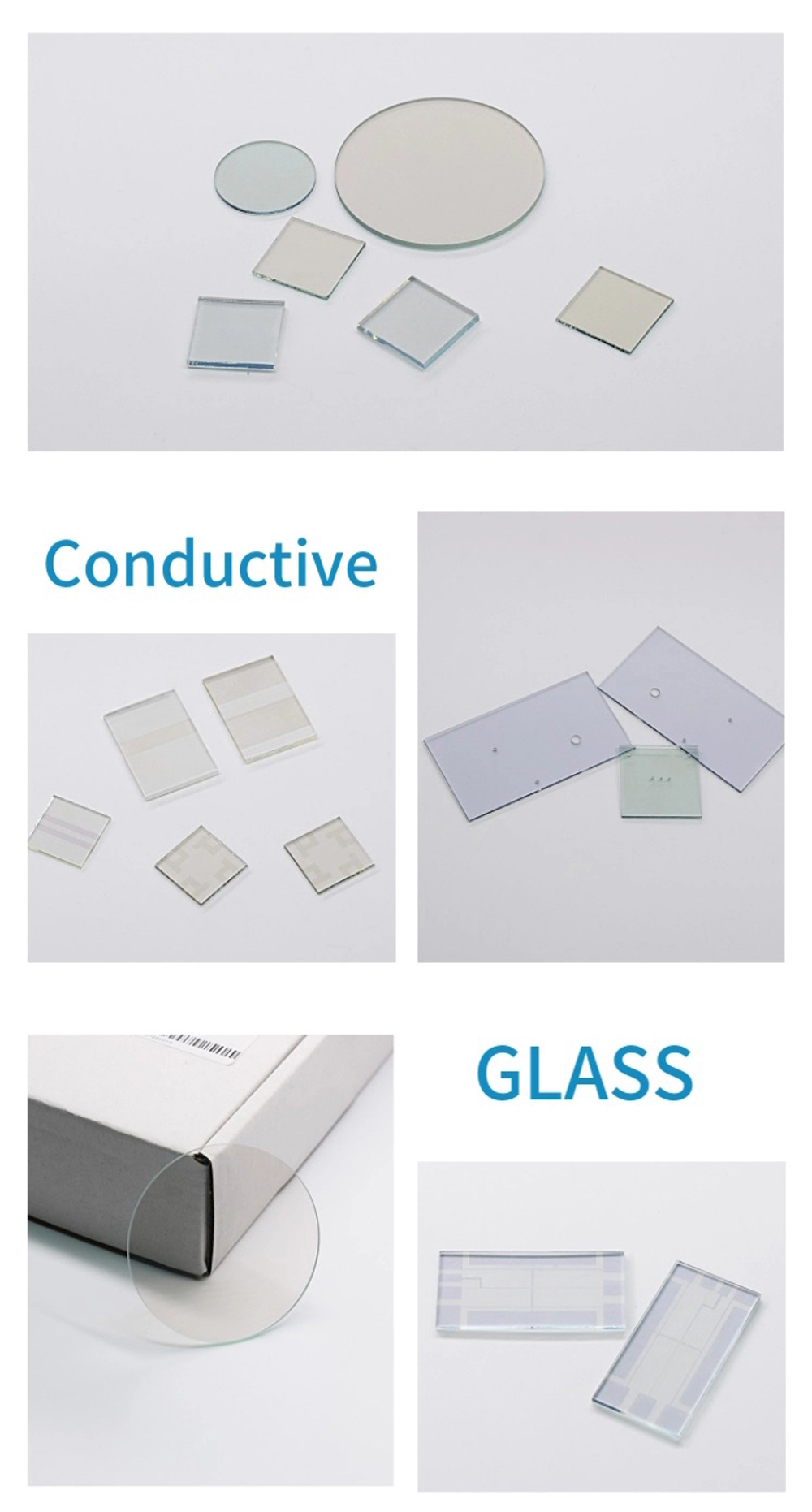

Dongguan Factory 5-100ohm Patterned ITO Glass 1.1mm Indium Tin Oxide Glass

As a replacement for ITO, it’s widely used in liquid crystal display, photocatalysis, thin film solar cell substrates, dye-sensitized solar cells, electrochromic glass and other fields. Also, FTO glass is a promising touch screen manufacturing technology that realizes the integration of glass and touch.

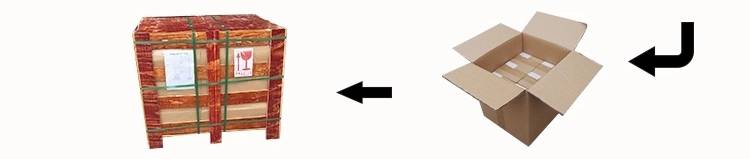

1. Packaging and transportation

- The packaging of ITO/FTO/AZO conductive glass is generally packaged in a paper-proof package (suitable for large-area or small-size glass packaging)

- or plastic-framed packaging (suitable for large-area packaging with large area, plastic frame and glass contact parts are generally not used) .

- After the conductive glass separator or the partition frame is separated, it is generally tightly packed with a shrink film or paper to prevent the sliding and rubbing between the glasses and between the glass and the package during transportation to affect the performance of the glass.

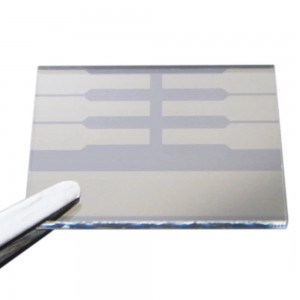

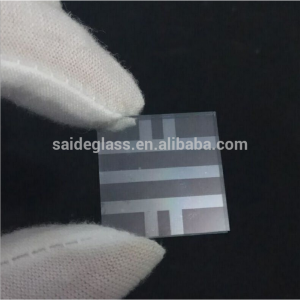

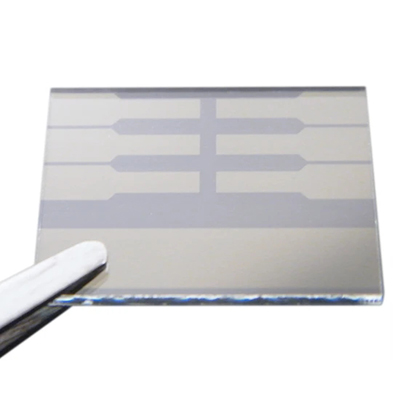

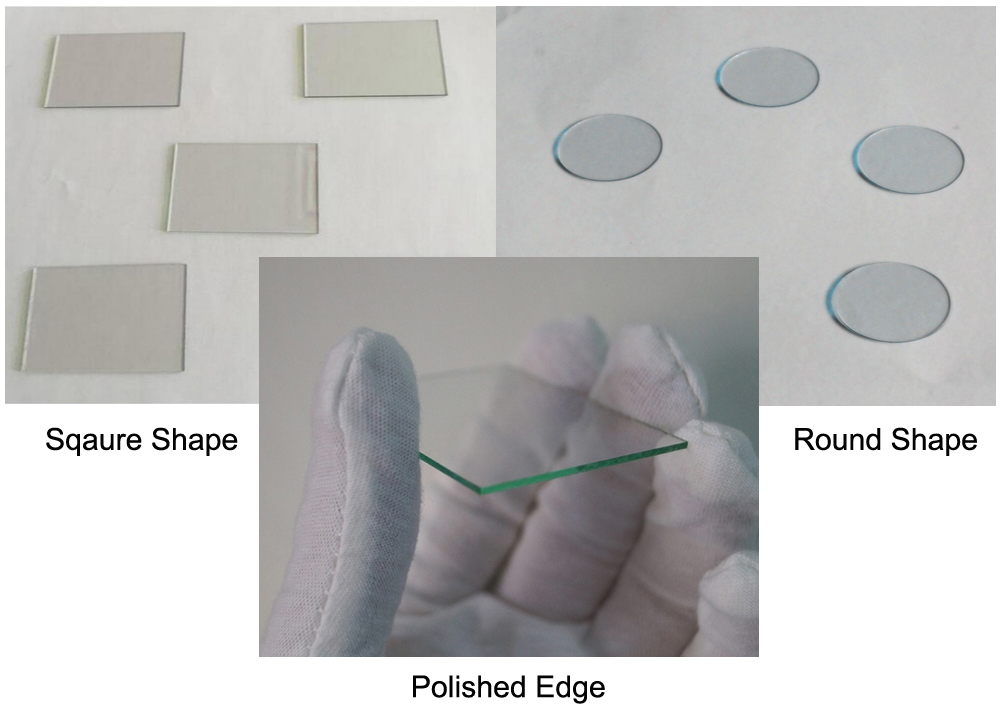

2. Etching of ITO conductive glass

We also offer etching services for ITO/FTO conductive glass. Please send us the graphics and dimensions.

After confirming your request, it will take about 10 days to customize, and then we can ship the goods for you.

- The conductive layer of IT0 conductive glass is indium tin oxide (IT0 for short) and easily reacts with acid.

- The concentration of hydrochloric acid is prepared according to the thickness of the IT0 conductive layer And the etching time.

- The hot hydrochloric acid can accelerate the etching process.

FACTORY OVERVIEW

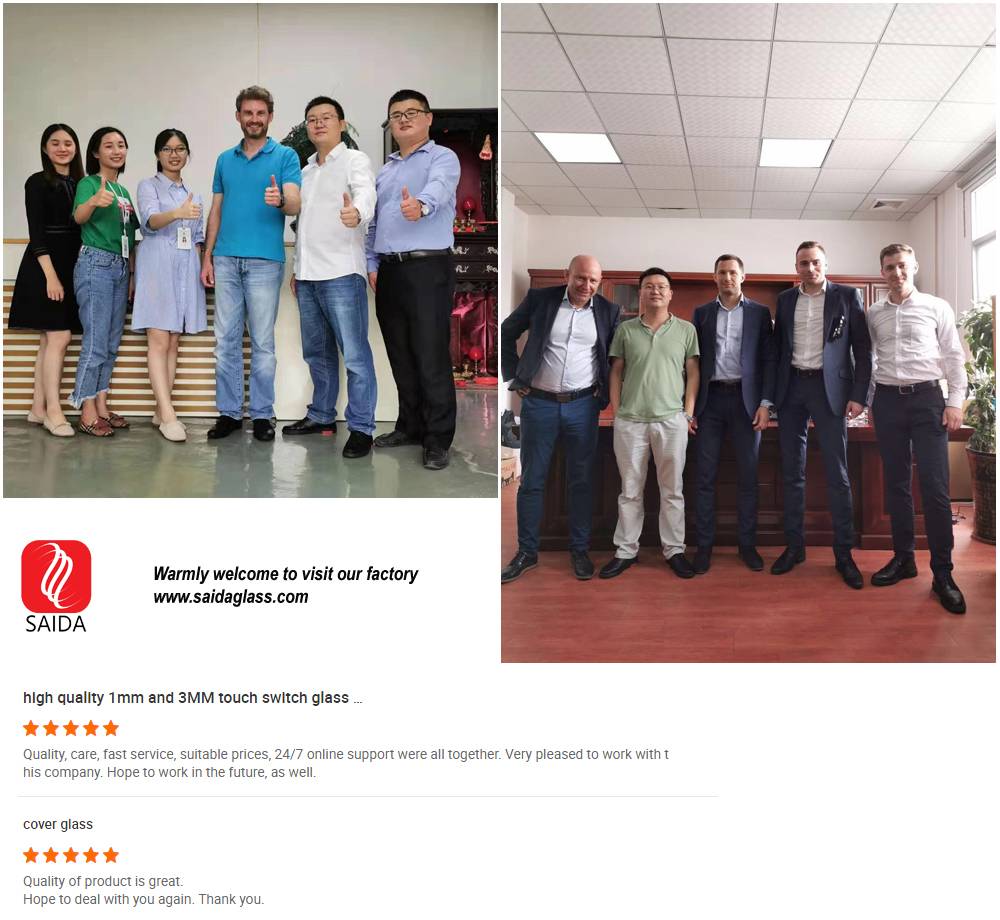

CUSTOMER VISITING & FEEDBACK

All MATERIALS USED ARE COMPLIANT WITH ROHS III (EUROPEAN VERSION), ROHS II (CHINA VERSION), REACH (CURRENT VERSION)

OUR FACTORY

OUR PRODUCTION LINE & WAREHOUSE

Lamianting protective film — Pearl cotton packing — Kraft paper packing

3 KIND OF WRAPPING CHOICE

Export plywood case pack — Export paper carton pack