Specification

1, Density—approx. 2.56 g / cm3

2, Modulus of Elasticity— approx. 93 x 103 Mpa

3, Bending Strength— approx. 36 MPa

The bending strength testing is to be accomplished according to DIN EN 1288 part 5 (R45).

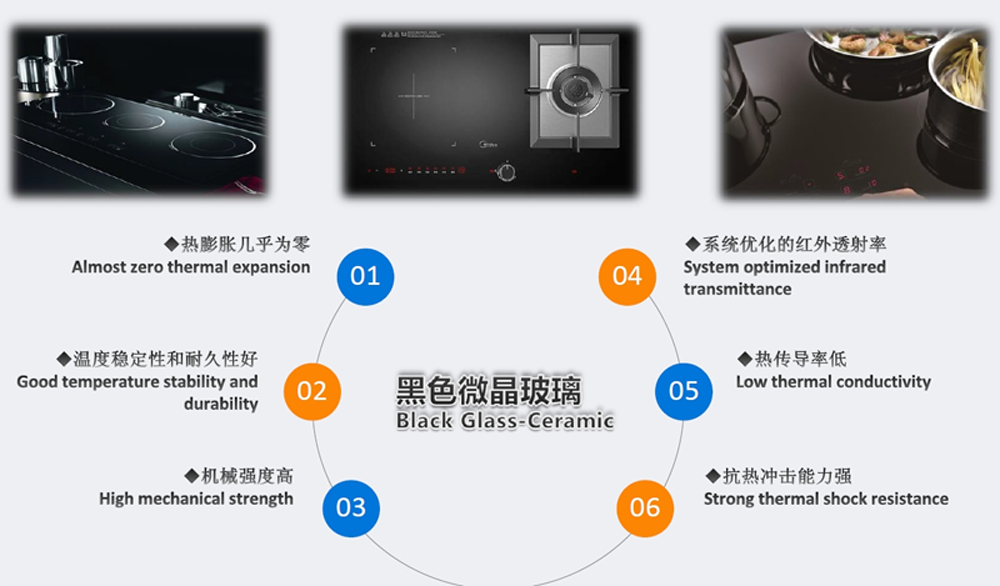

4. Thermal Characteristics

Coefficient of Mean Linear Expansion—α(20 – 700oC) (0 ± 0.5) x 10-7 /K

5. Resistance to Temperature Differences (RTD)

Resistance of the panel to temperature differences between heated zone and cold panel edge roomtemperature). No cracking due to thermal stress at Tes, max1<=700 degree C

6. Thermal Shock Resistance

Resistance of the panel to thermal shock when the hot panel (780 degree C) is quenched with cold water (20oC temperature). No cracking due to thermal stress at Tes, max<=700 degree C

7. Chemical Characteristics of Base Material

Acid Resistance— DIN 12116: at least class S3

Alkaline Resistance—based on ISO 695: at least class A2

8. Screen printing: complies with RoHS standards, normal ink available

9. Impact resistance: A steel ball (diameter 60mm, weight 188g) freefall from180mm height, striking the panel 10 times. No scratching or cracking.

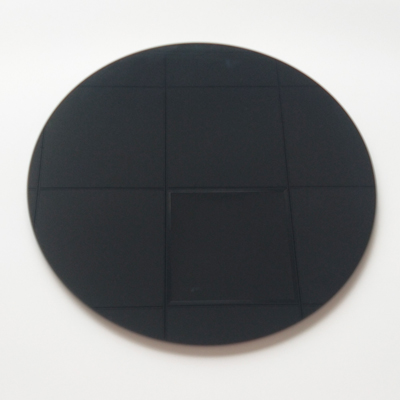

Applications

1.Vision panels for room heaters, glass heaters, glass heating tabletops, heat preservation board/panels;

2.Cover panels for heating radiators, drying stand, towel heaters;

3.Cover panels for reflectors and high performance floodlights

4.Cover panels in IR drying appliances

5.Cover panels for beamers

6.UV blocking shields

7.Cover panels for kebab grill radiators, electric heating fish bowl

8.Safety protection (bullet proof glass)

FACTORY OVERVIEW

CUSTOMER VISITING & FEEDBACK

All MATERIALS USED ARE COMPLIANT WITH ROHS III (EUROPEAN VERSION), ROHS II (CHINA VERSION), REACH (CURRENT VERSION)

OUR FACTORY

OUR PRODUCTION LINE & WAREHOUSE

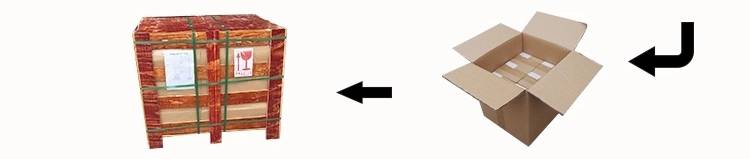

Lamianting protective film — Pearl cotton packing — Kraft paper packing

3 KIND OF WRAPPING CHOICE

Export plywood case pack — Export paper carton pack