PRODUCT INTRODUCTION

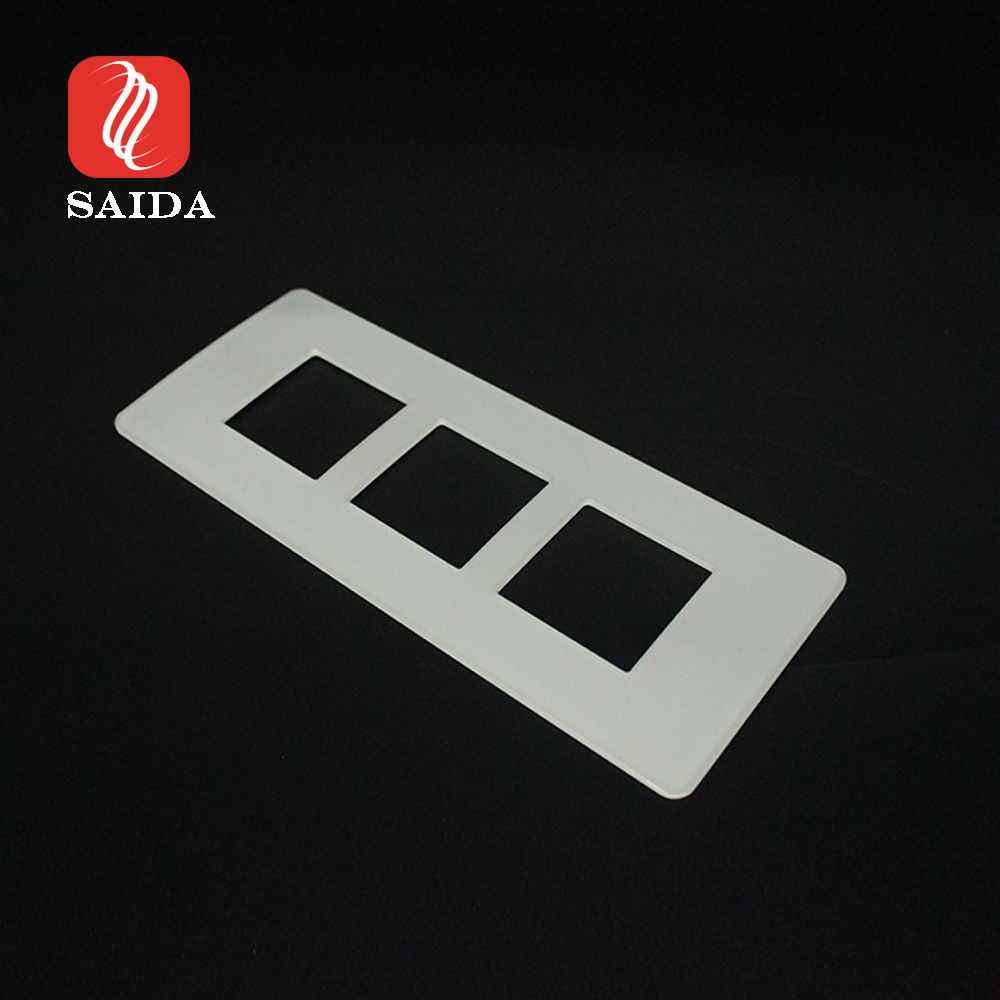

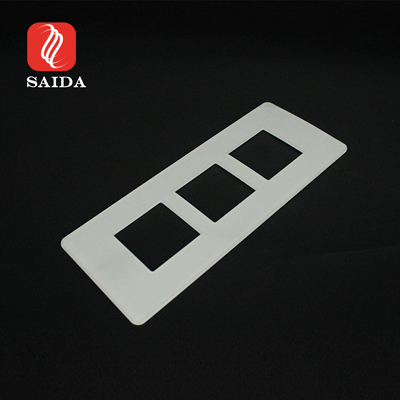

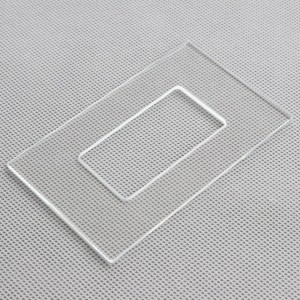

1. Details: round inner holes, rectangle inner holes, thickness 3mm and 4mm, clear surface, and well-polished straight flat edge with chamfer 0.5mm. Welcome to custom your design.

2. Processing: From cutting raw material – glass sheet into little pieces to making physical/heat tempering treatment, the processing procedures are done in our factory. And so is the screen printing step. The production volume reaches 2k – 3k per day. For customized request, that coating anti-fingerprint on the clear surface is workable, this keeps it dirt resistant and fingerprint resistant.

3. Better performance than acrylic glass (acrylic, actually a kind of plastic panel) in yellow resistance ability. The glass frame has a shiny crystal look. Adding a panel of glass to your light switch is just like adding an elegant design to your product, to create the more popular item in market.

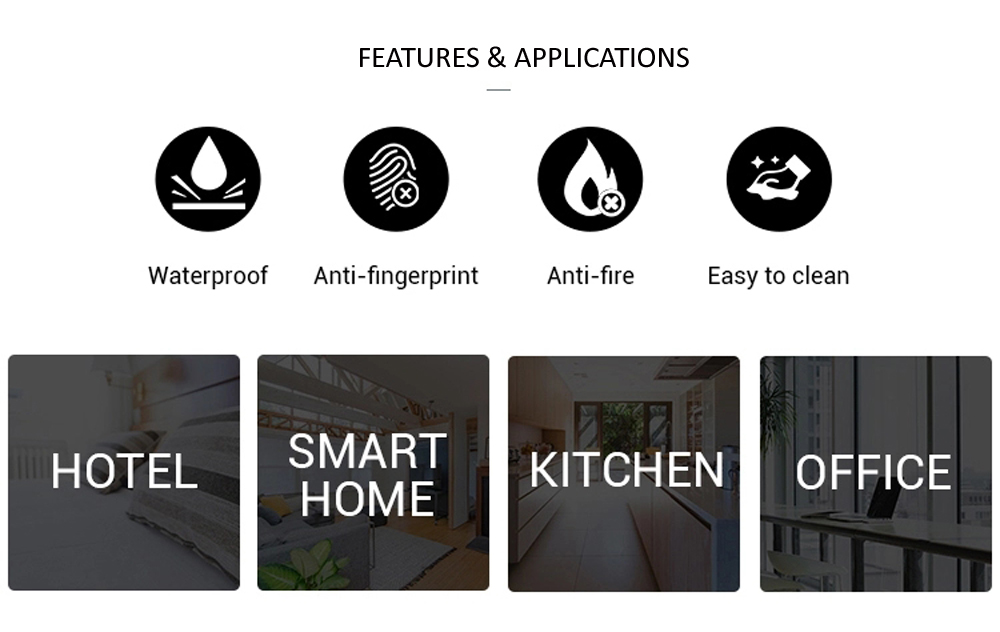

Application :

Be a decoration on light switch. Different printed colors fit to various themes rooms. Widely used in the interior decoration, such as in houses, hotels, offices, etc.

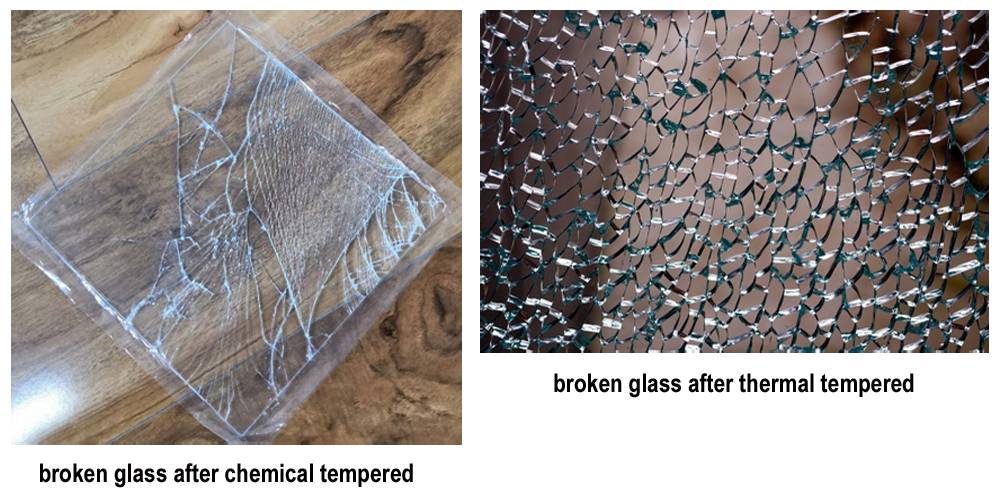

What is safety glass?

Tempered or toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the interior into tension.  FACTORY OVERVIEW

FACTORY OVERVIEW

CUSTOMER VISITING & FEEDBACK  All MATERIALS USED ARE COMPLIANT WITH ROHS III (EUROPEAN VERSION), ROHS II (CHINA VERSION), REACH (CURRENT VERSION)

All MATERIALS USED ARE COMPLIANT WITH ROHS III (EUROPEAN VERSION), ROHS II (CHINA VERSION), REACH (CURRENT VERSION)

OUR FACTORY

OUR PRODUCTION LINE & WAREHOUSE

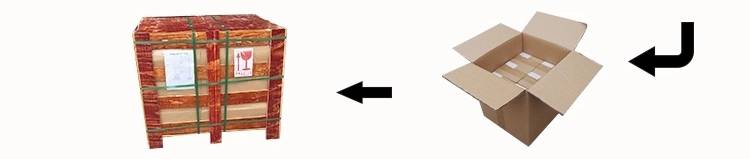

Lamianting protective film — Pearl cotton packing — Kraft paper packing

3 KIND OF WRAPPING CHOICE

Export plywood case pack — Export paper carton pack