Fasas

- 3.3 madaidaicin madaidaicin fadada

- juriya zazzabi mai zafi tare da sunadaraidattako

-Super Scratch mai tsayayya da ruwa mai ruwa & harshen wuta mai tsauri

-Cikakken lebur da santsi

-Tabbacin ranar isar da lokaci

-Daya zuwa Cire Tsarin Gudanarwa da Jagoranci

-Siffar, girma, finsh & zane za a iya tsara kamar buƙatu

-Anti-Glare / Anti-mai tunani / Anti-mai son magana / Anti-Songrobal ana samun ta a nan

Rahoton Kayan Gilashin Gilashi

| (Dennenity) | 2.30g / cm² |

| (Mohs Hardness) | 6.0MoHs ' |

| (Modulity modulus) | 67Knm - 2 |

| 抗张强度 (ƙarfin tensile) | 40 - 120nmm - 2 |

| (Poisson rabo) | 0.18 |

| 热膨胀系数 (20-400 ° C) (ingantaccen tasirin kan thermal) | (3.3) * 10` 6 |

| (90 ° C) (takamaiman aiki) | 1.2W * (m * k`-1) |

| (Grassextiitive Index) | 1.6375 |

| (Takamaiman zafi) (J / kg) | 830 |

| (Melting Point) | 1320 ° C |

| (Maɗaukaki) | 815 ° C |

| 连续工作温度 / 使用寿命 (ci gaba da zaman zazzabi na aiki / rayuwar sabis) | 150 ° C |

| ≥120000h (-60 ° C-150 ° C) | 200 ° C |

| ≥90000h (-60 ° C-200 ° C) | 280 ° C |

| ≥620000h (-60 ° C-280 ° C) | 370 ° C |

| ≥30000h | 520 ° C |

| ≥130000h | |

| ((Girgizar zafi) | ≤350 ° C |

| (Tasirin kaifi) | ≥7j |

| 主要化学成分% 含量 (babban kayan sunadarai%) | |

| SiO2 | 80.40% |

| Feed3 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na da2 + k20 | 4.20% |

| FE | 0.02% |

| (Haushi na ruwa) | Hgb 1 级 (HGB 1) |

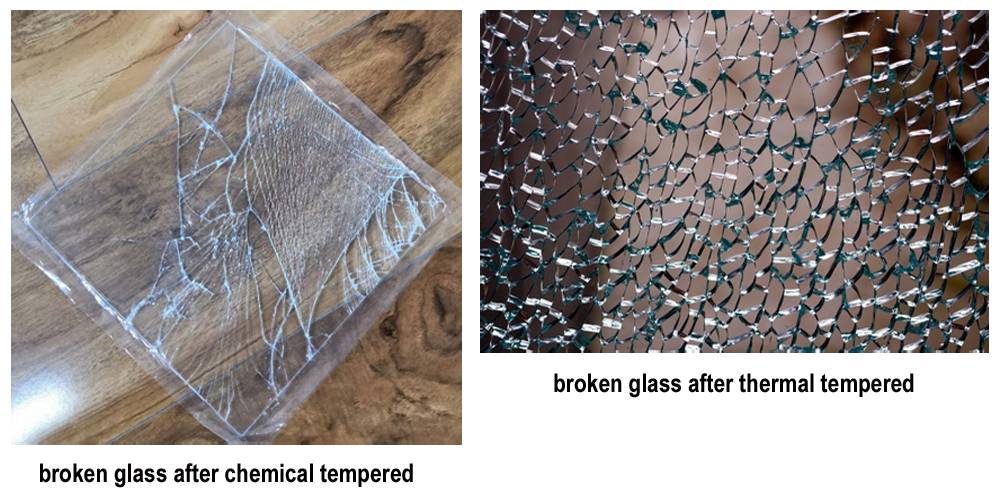

Menene gilashin aminci?

Gilashin da tougheded gilashin ne wani nau'in gilashin da ake sarrafawa ta hanyar da aka sarrafa ta hanyar da aka sarrafa shi ko magani don ƙara

karfinsa idan aka kwatanta da gilashin al'ada.

Zizuki yana sanya saman saman cikin matsawa da ciki cikin tashin hankali.

Fastocin masana'anta

Abokin ciniki yana ziyartar & Feedback

Duk kayan da aka yi amfani da su Yarda da Rohs III (Version), Rohs II (Version Version), kai (sigar yanzu)

Masana'antarmu

Layin samar da mu & shagonmu

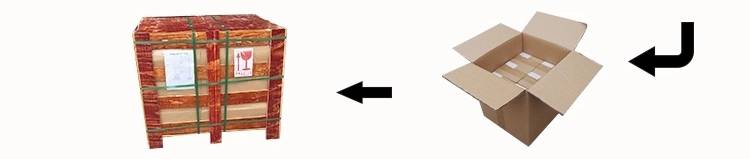

Lamianting mai kariya fim - fakitin cuble

3 nau'in zabi

Fitar da Proplywood Case Pack - Fakitin Takardar Takardar