NTA

- 3.3 Coefficient ntawm Thermal Expansion

- Kev kub siab tiv taus tshuaj lom neegkev ruaj khov

–Super khawb resistant & waterproof & hluav taws resistant

–Kev tiaj tiaj thiab du zoo meej

–Kev lees paub hnub xa khoom raws sijhawm

–Kev sib tham ib leeg thiab kev qhia txog kev tshaj lij

–Cov duab, qhov loj me, finsh & tsim tuaj yeem hloov kho raws li qhov kev thov

–Tiv thaiv kev ci ntsa iab / Tiv thaiv kev cuam tshuam / Tiv thaiv kev ntiv tes / Tiv thaiv kab mob me me muaj nyob ntawm no

Daim Ntawv Qhia Txog Cov Khoom Siv Iav Borosilicate Siab

| 密度 (Density) | 2.30g/cm² |

| Hardness | 6.0′ |

| Elasticity Modulus | 67KNmm – 2 |

| Tensile zog | 40 – 120Nmm – 2 |

| Poisson Ratio | 0.18 |

| 20-400 ° C (Coefficient ntawm Thermal Expansion) | (3.3)*10`-6 |

| 导热率比热 (90 ° C) (Tshwj xeeb thaum tshav kub kub conductivity) | 1.2W*(M*K`-1) |

| Kev ntsuas Refractive Index | 1.6375 |

| 比热 (Specific Heat) (J/KG) | 830 |

| Melting Point | 1320°C |

| 软化点 (Softening Point) | 815°C |

| 连续工作温度/使用寿命 (Kev khiav hauj lwm kub tsis tu ncua/Kev pab lub neej) | 150°C |

| ≥120000h (-60 ° C-150 ° C) | 200°C |

| ≥90000h (-60 ° C-200 ° C) | 280°C |

| ≥620000h (-60 ° C-280 ° C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| Kev Thermal Shock | ≤350 ° C |

| 抗冲击强度 (Impact Strength) | ≥7J |

| 主要化学成分% 含量 (Main Chemical Composition % Cov ntsiab lus) | |

| SiO2 | 80.40% |

| Fe203 ua | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性 (Water Tolerance) | HGB 1 (HGB 1) |

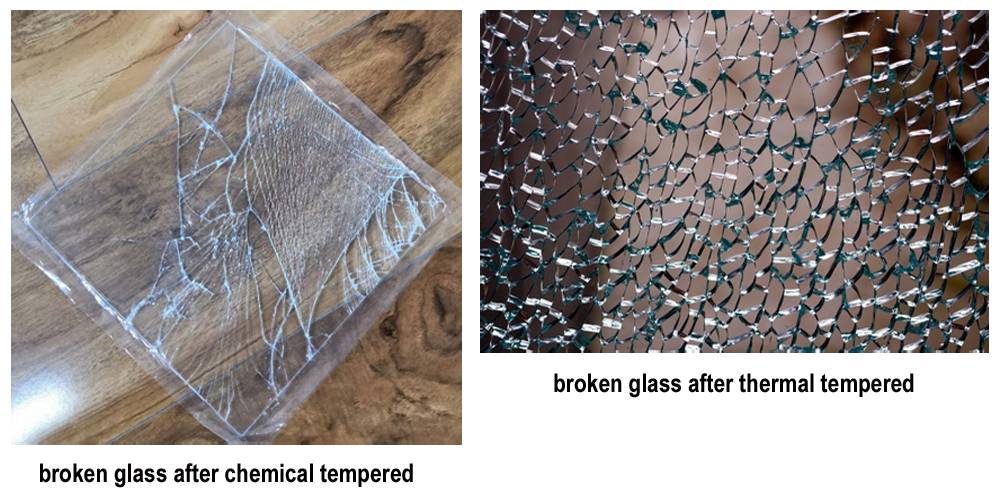

Iav kev nyab xeeb yog dab tsi?

Cov iav tempered lossis toughened yog ib hom iav kev nyab xeeb uas ua los ntawm kev tswj hwm thermal lossis tshuaj lom neeg kom nce

nws lub zog piv rau cov iav ib txwm.

Tempering ua rau cov nplaim sab nraud nruj thiab sab hauv nruj.

HOOBKAS TXHEEJ TXHEEM

COV NEEG SIV KHOOM MUS SAIB & COV LUS QHIA

Txhua yam khoom siv yog UA RAWS LI ROHS III (European Version), ROHS II (Suav Teb Version), REACH (Tam Sim No Version)

PEB LUB HOOBKAS

PEB COV KAB NTAU LAWM & LUB TSEV KHOOM

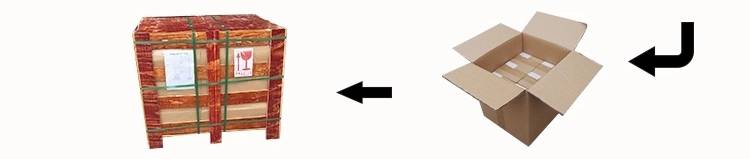

Zaj duab xis tiv thaiv lamianting - Pearl paj rwb ntim khoom - Kraft ntawv ntim khoom

3 HOM KEV XAIV QHAB NPAUM

Export plywood case pack — Export paper carton pack