Atụmatụ

– 3.3 Ọnụọgụ nke Mgbasawanye Okpomọkụ

- Ike iguzogide okpomọkụ dị elu na kemịkalụnkwụsi ike

–Na-eguzogide ọkọ nke ukwuu, na-anaghị amịpụta mmiri, na-eguzogidekwa ire ọkụ

–Nkwụsi ike na ịdị ire ụtọ zuru oke

–Nkwa ụbọchị nnyefe n'oge

–Ndụmọdụ na nduzi ọkachamara n'otu n'otu

–Ụdị, nha, ọdịdị na imewe nwere ike ahaziri dịka achọrọ

–Ọgwụ mgbochi-enwu/Mgbochi-mgbapụta/Mgbochi-mkpisiaka/Mgbochi-mikrobi dị ebe a

Akụkọ Ihe Iko Borosilicate Dị Elu

| Njupụta (Njupụta) | 2.30g/cm² |

| Isi ike (ike) | 6.0′ |

| 弹性模量(Elasticity Modulus | 67KNmm – 2 |

| 抗张强度( Ike tensile | 40 – 120Nmm – 2 |

| 泊松比(Ratio Poisson | 0.18 |

| 热膨胀系数 (20-400°C((Coefficient of Thermal Expansion) | (3.3)*10`-6 |

| 导热率比热(90°C)(Specific Heat Conductivity) | 1.2W*(M*K`-1) |

| 折射率 (Refractive Index) | 1.6375 |

| 比热(Specific Heat) (J/KG) | 830 |

| Ebe mgbaze (Melting Point) | 1320°C |

| 软化点 (Ebe Ntụgharị) | 815°C |

| 连续工作温度/使用寿命 (Ndụ ọrụ okpomọkụ na-aga n'ihu) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Mmetụta Mmetụta) | ≥7J |

| 主要化学成分%含量(Main Chemical Composition % Content) | |

| SiO2 | 80.40% |

| Fe203 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性(Anya ndidi mmiri) | HGB 1 (HGB 1) |

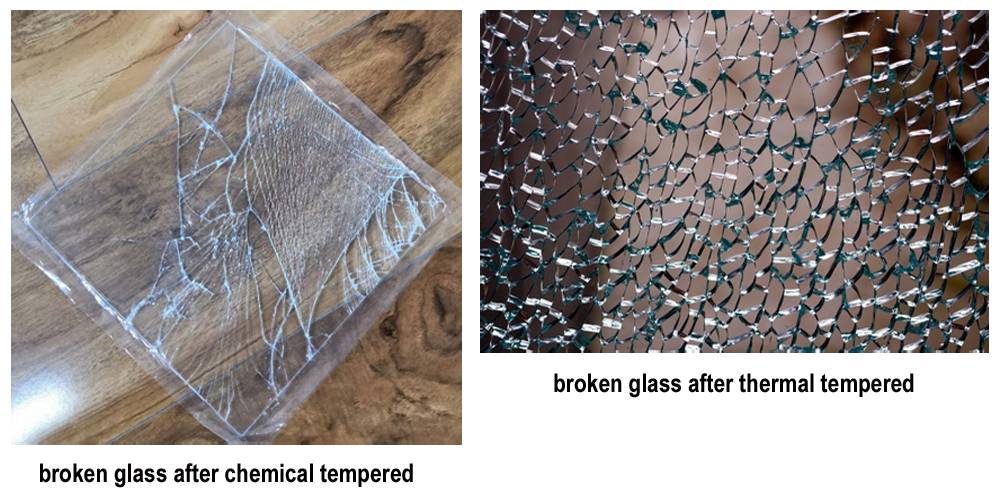

Gịnị bụ iko nchekwa?

Iko siri ike ma ọ bụ nke siri ike bụ ụdị iko nchekwa nke ejiri ọgwụgwọ okpomọkụ ma ọ bụ kemịkalụ a na-achịkwa hazie iji mụbaa

ike ya ma e jiri ya tụnyere iko nkịtị.

Ịgba ume na-etinye elu mpụta n'ime nrụgide na ime ya n'ime nrụgide.

NYOCHA Ụlọ Ọrụ Mmepụta Ihe

Nleta na nzaghachi nke ndị ahịa

Ihe niile ejiri mee ihe bụ N'IME ROHS nke Atọ (Ụdị Europe), ROHS nke Abụọ (Ụdị China), REACHỊ (Ụdị Ugbu a)

Ụlọ ọrụ anyị

AHỊA MMỤTA NA ỤLỌ NKWÀ ANYỊ

Ihe mkpuchi nchekwa na-egbuke egbuke — Nkwakọba owu Pearl — Nkwakọba akwụkwọ Kraft

Ụdị nhọrọ mkpuchi atọ

Mbupụ ngwugwu plywood — Mbupụ ngwugwu katọn akwụkwọ