NGA WHAKAMAHI

– 3.3 Whakarea o te Roha Ngawha

– Te ātete ki te pāmahana teitei me te matūpūmautanga

–Super raraku ātete & parewai & mura ātete

–Te papatahi me te ngawari

–Te whakapumautanga o te ra tuku tika

–Kotahi ki te kotahi te tohutohu me te arahi ngaio

–Ko te ahua, te rahi, te ahua me te hoahoa ka taea te whakarite hei tono

–Anti-glare/Anti-reflective/Anti-fingerprint/Anti-microbial kei konei

Teitei o te Ripoata o te Karaehe Karaehe borosilicate

| 密度(Density) | 2.30g/cm² |

| 硬度( pakeke) | 6.0' |

| 弹性模量(Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度(Tensile Strength) | 40 – 120Nmm – 2 |

| 泊松比(Poisson Ratio) | 0.18 |

| 热膨胀系数 (20-400°C)(Koefficient of Thermal Roha) | (3.3)*10`-6 |

| 导热率比热(90°C)(Te Kawenga Wera Motuhake) | 1.2W*(M*K`-1) |

| 折射率(Refractive Index) | 1.6375 |

| 比热(Wehana Tauwhāiti) (J/KG) | 830 |

| 熔点(Ira Whakarewa) | 1320°C |

| 软化点(Ira Whakangohengohe) | 815°C |

| 连续工作温度/使用寿命(Te Wehenga Mahi Tonu/Te Ora Ratonga) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Waariki Rua) | ≤350°C |

| 抗冲击强度(Te Kaha Paanga) | ≥7J |

| 主要化学成分%含量(Tito Matū Matua % Ihirangi) | |

| SiO2 | 80.40% |

| Fe203 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性(Water tolerance) | HGB 1级 (HGB 1) |

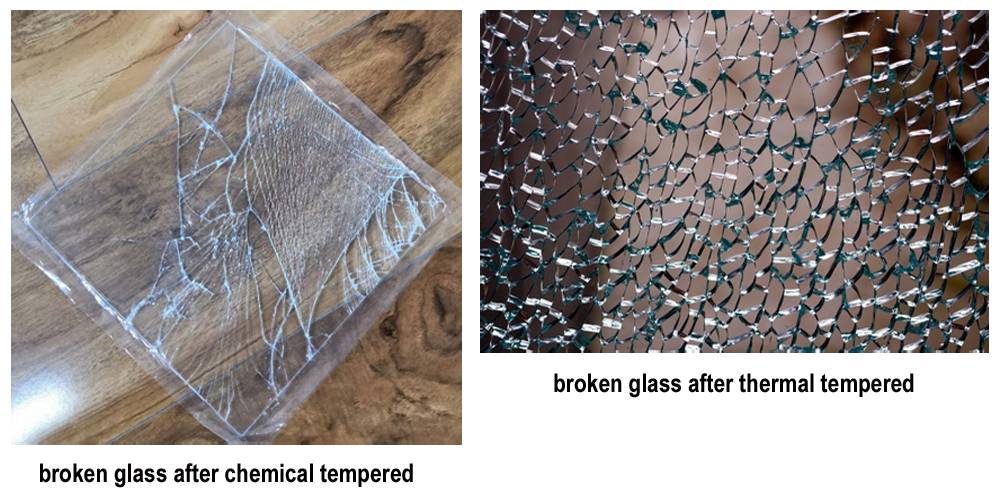

He aha te karaihe haumaru?

Ko te karaehe whakamaarama, he momo karaehe haumaru ka tukatukahia e te whakamaarama waiariki, matū matū ranei kia piki ake

tona kaha i whakaritea ki te karaihe noa.

Ko te whakamaarama ka kuhu nga mata o waho ki roto ki te mahanga, me te roto o roto ki te mariri.

WHAKAMAHI WHAKAMAHI

TE HAERE ME TE WHAKAARO

Ko nga mea katoa e whakamahia ana HE WHAKAMAHI KI TE ROHS III (PUTANGA PAKEHA), ROHS II (PUTANGA HINA), REACH (PUTANGA O NAIANEI)

TO TATOU WAKARANGA

TA TATOU RANGA WHAKATANGA me te whare putunga

Kiriata whakamarumaru Lamianting — Tarapi miro peara — Tarapi pepa Kraft

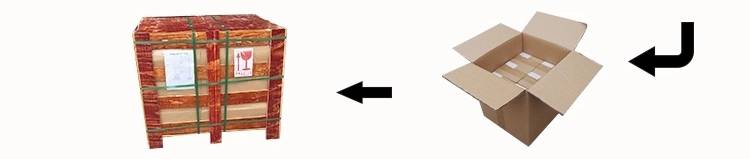

3 TE TINO KORERO TAKAI

Kawea atu te kete putea plywood - Kaweake te kete kaata pepa