Glass edging is to remove the sharp or raw edges of glass after cutting. The purpose is done for safety, cosmetics, functionality, cleanliness, improved dimensional tolerance, and to prevent chipping. A sanding belt/machining polished or manual grinding is used to sand off the sharps lightly.

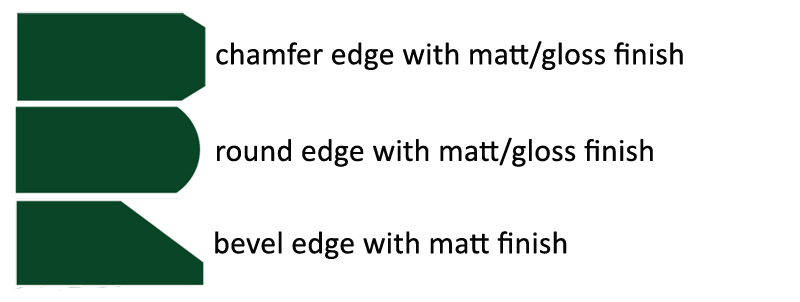

There are 5 edge treatments which are usually used.

| Edge Treatment | Surface Look |

| Seamed/swipe edge | Gloss |

| Chamfer/flat polished edge | Matt/Gloss |

| Round/pencil grinded edge | Matt/Gloss |

| Bevel edge | Gloss |

| Step edge | Matt |

So, what do you select the edgework when designing the product?

There are 3 features for selecting:

- Assembly way

- Glass thickness

- Size tolerance

Seamed/swipe edge

It is a type of glass edging to ensure the finished edge is safe for handling but not used for decorative purposes. Therefore, it is ideal for applications which the edge are not exposed, such as the glass installed into the frame of fireplace doors.

This type of edging is a smooth chamfer top and bottom with an exterior ground edge. It is most often see on frameless mirrors, display cover glass, lighting decorative glass.

The edging is achieved by the use of a diamond-embedded grinding wheel, which can create a slightly rounded edge and allows for a frosty, stain, matt or gloss, polished glass finish. ‘’Pencil’’ refers to the edge radius and it is similar to a pencil. Normally used for furniture glass, like table glass.

It is a kind of edge for a more cosmetics purpose with a gloss finish, usually used for mirrors and decorative glass.

This method involves cutting the edges of the glass and then using polishing unit bevel polishing them. It is a special edge treatment for glass with matt finish which assembled in a access like frame for lighting glass or thicker decorative glass.

Saida Glass can provide a variety of glass edgework methods. To learn more about the difference of edgework, contact us NOW!

Post time: Oct-27-2021