This article is mean to give every reader a very clear understanding of anti-glare glass, the 7 key properties of AG glass, including Gloss, Transmittance, Haze, Roughness, Particle Span, Thickness and Distinctness of Image.

1. Gloss

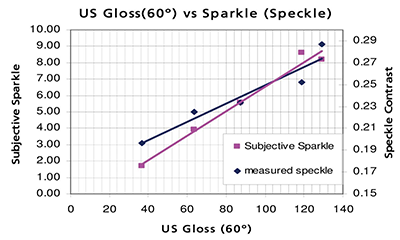

Gloss refers to the degree that the surface of the object is close to the mirror, the higher the gloss, the more mirror-likely glass surface. The main usage of AG glass is anti-glare, its main principle is diffuse reflection which measured by Gloss.

The higher the gloss, the higher the clarity, the lower the haze; the lower the gloss, the higher the roughness, the higher the anti-glare, and the higher the haze; the gloss is directly proportional to the clarity, the gloss is inversely proportional to the haze, and inversely proportional to the roughness.

Gloss 110, used in automotive industry: “110+AR+AF” is the standard for automotive industry.

Glossiness 95, used in indoor bright light environment: such as medical equipment, ultrasound projector, cash registers, POS machines, bank signature panels and so on. This type of environment mainly consider the relationship between gloss and clarity. That is, the higher the gloss level, the higher the clarity.

Gloss level below 70, suitable for outdoor environment: such as cash machines, advertising machines, train platform display, engineering vehicle display (excavator, agricultural machinery) and so on.

Gloss level below 50, for areas with strong sunlight: such as cash machines, advertising machines, displays on train platforms.

Gloss of 35 or less, applicable to touch panels: such as computer mouse boards and other touch panels that do not have a display function. This type of product utilizes the “paper-like touch” feature of AG glass, which makes it smoother to touch and less likely to leave fingerprints.

2. Light Transmittance

In the process of light passing through the glass, the ratio of the light projected and passing through the glass to the light projected is called transmittance, and the transmittance of AG glass is closely related to the value of gloss. The higher the gloss level, the higher the transmittance value, but not higher than 92%.

Testing standard: 88% Min. (380-700nm visible light range)

3. Haze

Haze is the percentage of the total transmitted light intensity that deviates from the incident light by an angle of more than 2.5°. The greater the haze, the lower the gloss, transparency and especially imaging. The cloudy or hazy appearance of the interior or surface of a transparent or semi-transparent material caused by diffuse light.

4. Roughness

In mechanics, roughness refers to the micro-geometric properties consisting of smaller pitches and peaks and valleys that are present on a machined surface. It is one of the problems in the study of interchangeability. Surface roughness is generally shaped by the machining method it employs and other factors .

5. Particle Span

Anti-glare AG glass particle span is the size of the diameter of the surface particles after the glass is etched. Usually, the shape of AG glass particles is observed under an optical microscope in microns, and whether the span of particles on the surface of AG glass is uniform or not is observed through the image. Smaller particle span will have higher clarity.

6.Thickness

Thickness refers to the distance between the top and bottom of the anti-glare AG glass and the opposite sides, the degree of thickness. Symbol “T”, unit is mm. different glass thickness will affect its gloss and transmittance.

For AG glass below 2mm, the thickness tolerance is more stringent.

For example, if a customer requires a thickness of 1.85±0.15mm, it needs to be tightly controlled during the production process to ensure that it meets the standard.

For AG glass over 2mm, the thickness tolerance range is usually 2.85±0.1mm. this is because glass over 2mm is easier to control during the production process, so the thickness requirements are less stringent.

7. Distinctness of Image

AG glass glass DOI is generally related to the particle span indicator, the smaller the particles, the lower the span, the greater the pixel density value, the higher the clarity; AG glass surface particles are like pixels, the finer the more, the higher the clarity.

In practical applications, it is very important to choose the right thickness and specification of AG glass to ensure that the desired visual effect and functional requirements are achieved. Saida Glass offers various types of AG glass, combining your needs with the most suitable solution.

Post time: Mar-04-2025