AR coating glass is formed by adding multi-layer Nano-optical materials on the glass surface by vacuum reactive sputtering to achieve the effect of increasing the transmittance of the glass and reducing the surface reflectivity. Which the AR coating material is composed up by Nb2O5+SiO2+ Nb2O5+ SiO2.

AR glass mainly used as protection purpose for display screens, such as: 3D TVs, tablet computers, mobile phone panels, Media advertising machines, educational machines, cameras, medical instruments and industrial display equipment, etc.

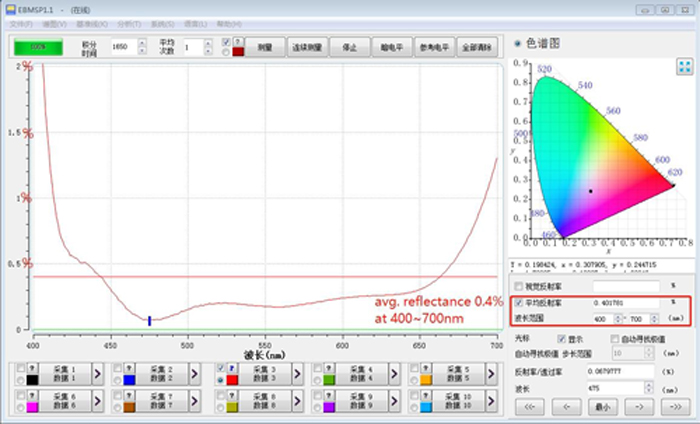

Normally, the transmittance can increase 2-3% for one sided AR coated glass with maximum transmittance 99% and minimum reflectivity below 0.4% for double sided AR coated glass. It depends on customer’s mainly focus on high transmittance or low reflectivity. Saida Glass is able to adjust it per customer’s request.

After applied AR coating, the glass surface will become smoother than standard glass surface, if directly attached to the back sensors, the tape cannot stick it very tight, thus glass will facing falls off possibility.

So, what should we do if the glass added AR coating on two sides?

1. Adding AR coating on glass two sides

2. Printing the black bezel at one side

3. Applying the tape at the black bezel area

If only need AR coating on one side? Then suggest like below:

1. Adding AR coating at the glass front side

2. Printing the black frame at the glass back side

3. Attaching the tape the at the black bezel area

The above method will help to maintain the adhesive attachment strength, thus won’t happen tape peeling off issues.

Saida Glass specialized in solving customer difficulties for win-win cooperation. To learn more, freely contact our expert sales.

Post time: Sep-13-2022