-

Glass Silkscreen Printing Color Guide

Saidaglass as one of China top glass deep processing factory provides one stop services including cutting, CNC/Waterjet polishing, chemical/thermal tempering and silkscreen printing. So, what is the color guide for silkscreen printing on glass? Commonly and globally, Pantone Color Guide is the 1s...Read more -

Happy Thanksgiving Day

To all our distinguished Customers and Friends, wish you all enjoy a wonderful and great Thanksgiving day and wish you and your family all the best for good. Let’s see the origin of Thanksgiving Day:Read more -

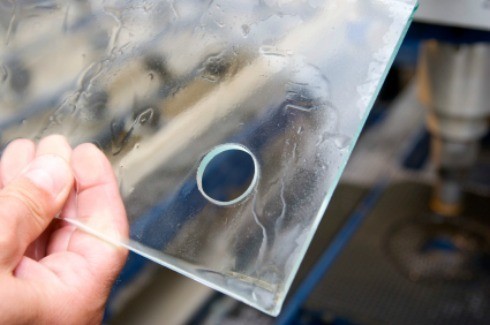

Why Drilling Hole size should same as glass thickness at least?

Thermal tempered glass which is a glass product by changing its inner Central Stress through heating the soda lime glass’s surface close to its softening point and cool it rapidly (usually also called air-cooling). The CS for thermal tempered glass is 90mpa to 140mpa. When drilling size is le...Read more -

What is the procedure for producing transparent icon?

When customer requires transparent icon, there are numbers of processing way to match it. Silkscreen Printing Way A: Leave the icon hollow cut when silkscreen printing one or two layers of background color. The finished sample will like below: Front ...Read more -

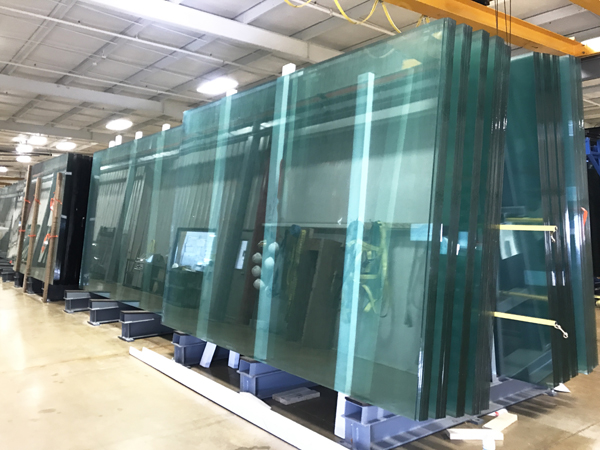

Glass Application

Glass as a sustainable, fully recyclable material which provides numrous environmental benefits such as contributing to mitigating climate change and saving precious natural resources. It is applied on lots of products that we use every day and see every day. Definitly, the modern life can not bu...Read more -

Evolutionary History of Switch Panels

Today, let’s talk about the evolutionary history of switch panels. In 1879, since Edison invented the lamp holder and switch, it has officially opened the history of switch, socket production. The process of a small switch was officially launched after The German electrical engineer Augusta Lausi...Read more -

Happy Halloween

To all our distinguished customer: When black cats prowl and pumpkins gleam, may luck be yours on Halloween~Read more -

How to count Cutting Rate of Glass?

Cutting Rate refers to the qty of qualified required glass size after glass cutted before polishing. The Formula is qualified glass with required size qty x required glass length x required glass width / raw glass sheet length / raw glass sheet width=cutting rate So at first, we should get a ver...Read more -

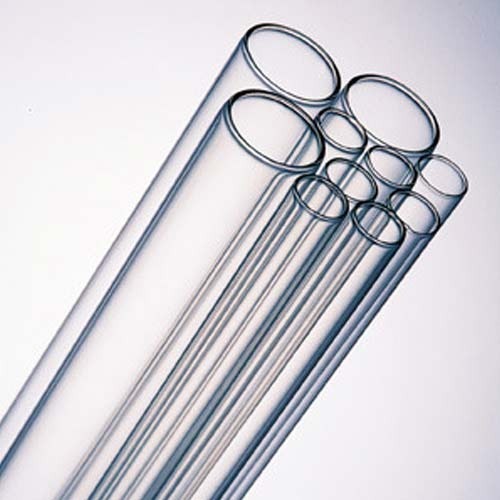

Why we call borosilicate glass as hard glass?

High borosilicate glass (also known as hard glass), is characterized by the use of glass to conduct electricity at high temperatures. The glass is melted by heating inside of the glass and processed by advanced production processes. The coefficient to thermal expansion is (3.3±0.1)x10-6/K, also k...Read more -

Standard Edgework

When cutting a glass it leaves a sharp edge on the top and bottom of the glass. That’s why numerous edgework occurred: We offer a number of different edge finishes to meet your design requirement. Find out below up to date edgework types: Edgework Sketch Description Application...Read more -

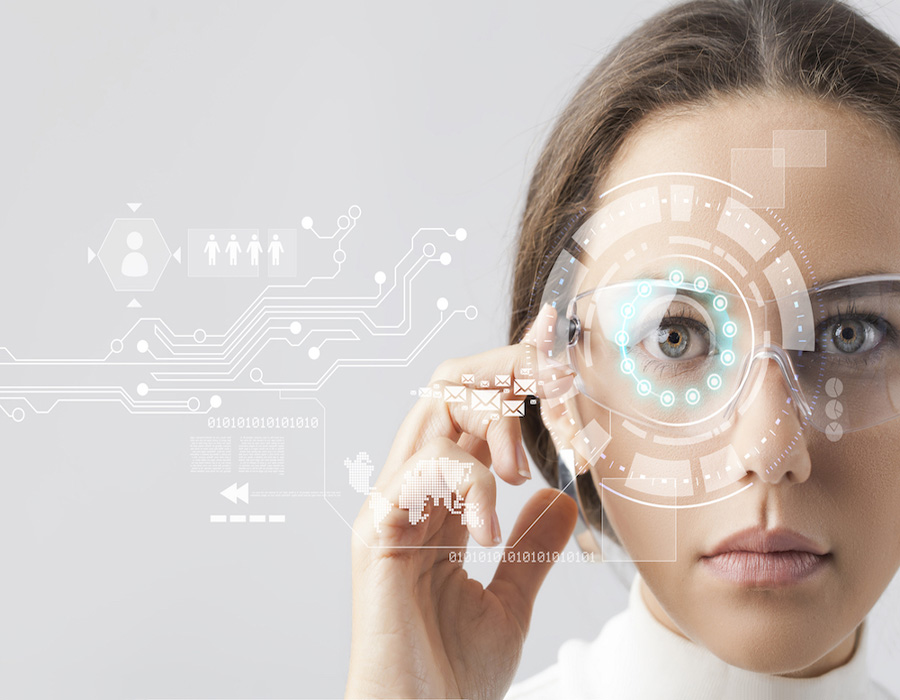

The Future of Smart Glass and Artificial Vision

Facial recognition technology is developing at an alarming rate, and glass is actually a representative of modern systems and is at the core point of this process. A recent paper published by the University of Wisconsin-Madison highlights the progress in this field and their “intelligence&#...Read more -

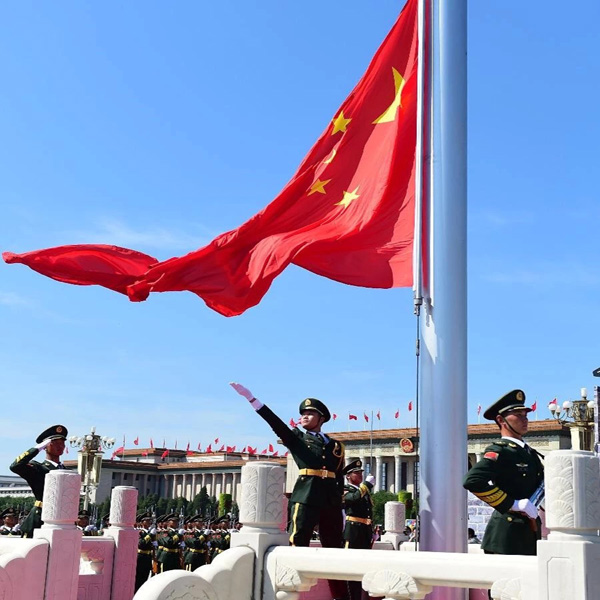

Holiday Notice-Naitonal Day

To our distinguish customer: Saida will be in National Day holiday for celebrating the 70th anniversary of the founding of the people’s Republic of China from 1st Oct. to 6th Oct. For any emergency, please call us or drop an email.Read more