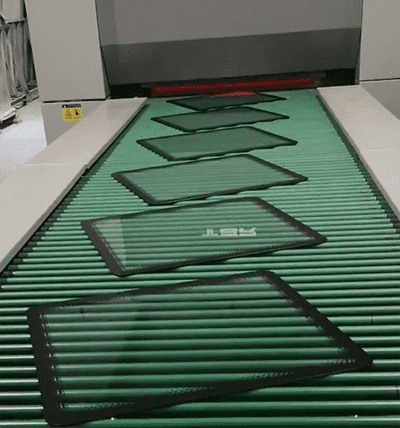

The tempering of flat glass is achieved by heating and quenching in a continuous furnace or a reciprocating furnace. This process is usually carried out in two separate chambers, and the quenching is carried out with a large amount of air flow. This application can be a low-mix or low-mix large volume.

Application point

During tempering, the glass is heated to the point where it becomes soft, but excessive heating will lead the deformation in the glass. Process setting for glass thickness is a time-consuming trial and error process. Low-E glass may be difficult to heat because it is used to reflect the infrared part of heat energy. To set up and continuously monitor the process thereafter, it is necessary to find ways to accurately measure the glass temperature.

What we do:

– Record the temperature of different kind of glass plate

– Monitor “inlet to outlet” temperature curve to optimize the heating and cooling process

– Random inspect 2 to 5pcs glass for each lot after finished tempering

– Ensure 100% qualified tempered glass arrive at customer

Saida Glass consistently strives to be your reliable partner and let you feel the value-added services.

Post time: Jul-24-2020