From the development of traditional silkscreen printing technology to in the past few decades to the UV printing process of UV flat-panel printers in recent years, to the high temperature glass glaze process technology that has emerged in the past year or two, these printing technologies have been widely used in the glass deep processing industry.

Glass materials are commonly used in China’s market and is one of the widely used materials, after secondary processing, the value of glass can be greatly improved, with the development of industry demand, from the original monochrome printing decoration to UV printing process, the current glass printing process has undergone a qualitative change. The traditional silkscreen printing of glass have color restrictions, the more colors printed, the lower yield occurred, and cumbersome plate making, printing, artificial color matching, etc., need a lot of human and material support, and the printing raw materials has different degrees of pollution to the environment. Under the stricter environmental protection control, the printing industry has introduced a new printing technology UV printing process – UV flat-panel printer;

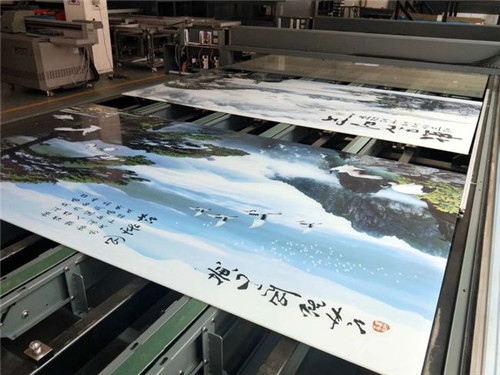

The emergence of UV flat-panel printers replace a lot of existing traditional printing technology, to solve the traditional printing process of innate shortcomings, because uv flat-panel printer unlimited material printing characteristics, it can be widely used not only in the glass processing industry, but also can be applied to decoration, decoration industry, signage, exhibition shows and other industries, UV flat-panel printers are computer CNC printing, automatic color matching without color restrictions, a large number of imaging, saving a lot of artificial material costs, but also in line with national environmental protection requirements; , the use of UV flat-panel printer printed glass, outdoor after a long period of sunlight, acid rain corrosion will change color and fall off.

Saida glass is a ten years glass processing expert, not only can produce traditional silk-print tempered glass, but also can provide high-temperature silk-printed tempered glass with AG/AR/AF treatment.

Post time: Jan-29-2021