We are frequently asked by our customer, ‘why there is a sampling cost? Can you offer it without charges? ’ Under typical thinking, the production process seems very easy with just cutting the raw material into required shape. Why there have jig costs, printing costs something etc. occurred?

Following I will list the cost during all related process of customize cover glass.

1. The cost of raw material

Choosing different glass substrate, like soda lime glass, aluminosilicate glass or other glass brands like Corning Gorilla, AGC, Panda etc, or with special treatment on the glass surface, like etched anti-glare glass, all of them will affect the production cost of producing samples.

Usually will need put 200% raw material double of the required quantity to make sure the final glass can meet the target quality and quantity.

2. The cost of CNC jigs

After cutting the glass into required size, all the edges are very sharp which need to do edge & corner grinding or hole drilling by CNC machine. A CNC jig in 1:1scale and bistrique are essential for edge process.

3. The cost of chemical strengthen

The chemical strengthening time usually will take 5 to 8hours, the time is variable according to different glass substrate, thickness and required strengthening data. Which means the furnace can not proceed different items at the same time. During this process, there will have electric charge , potassium nitrate and other charges.

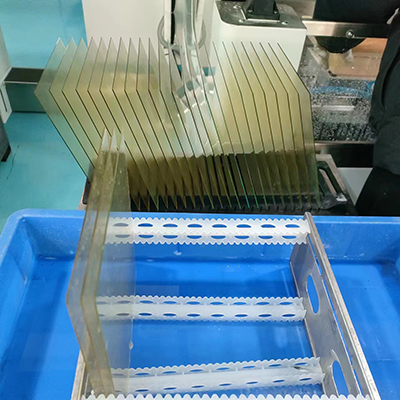

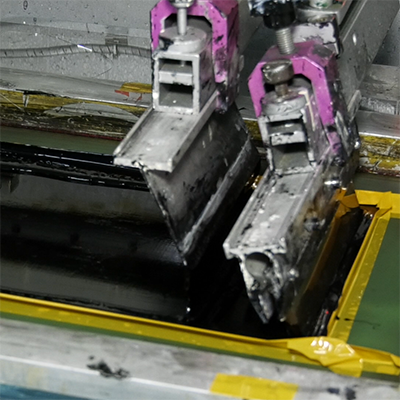

4. The cost of silkscreen printing

For silkscreen printing, each color and printing layer will need an individual printing mesh and film, which are customized per design.

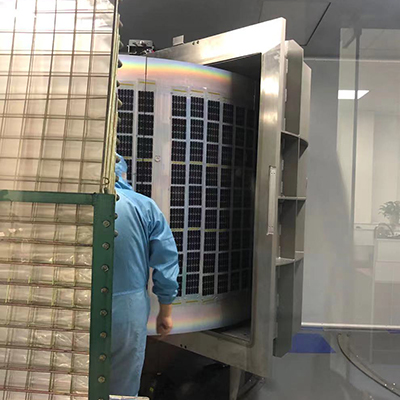

5. The cost of surface treatment

If need surface treatment, like anti-reflective or anti-fingerprint coating, it will involve adjusting and opening cost.

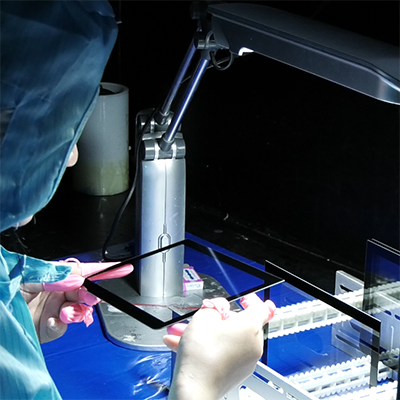

6. The cost of labor

Each process from cutting, grinding, tempering, printing, cleaning, inspection to package, all the process have adjusting and labor cost. For some glass with complex process, it may need half day to adjust, after done for production, it may only need 10 minutes to finish this process.

7. The cost of package and transit

The final cover glass will need double sided protective film, vacuum bag package, export paper carton or plywood case, to ensure it can be delivered to customer safely.

Saida Glass as a ten years glass processing manufacture, aiming to solve customer difficulties for win-win cooperation. To learn more, freely contact our expert sales.

Post time: Dec-04-2024