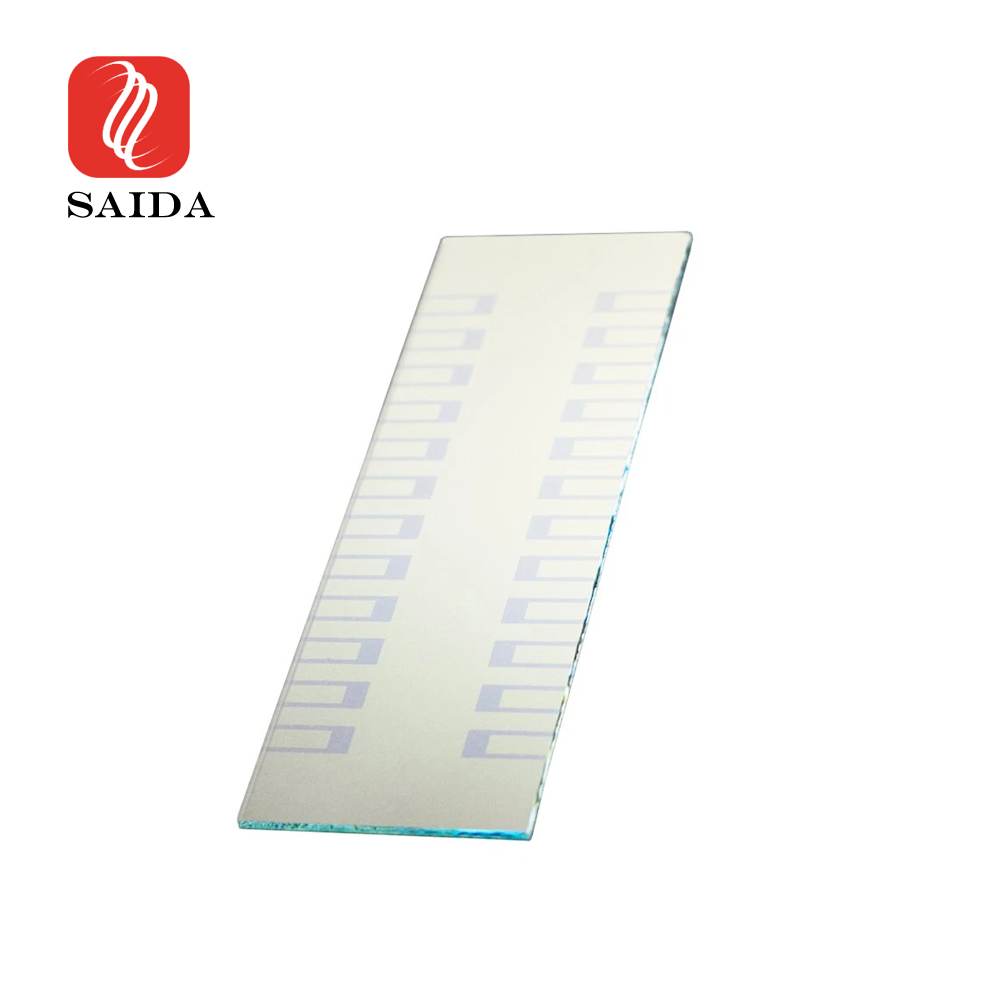

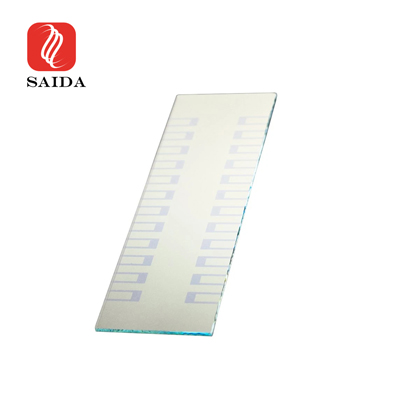

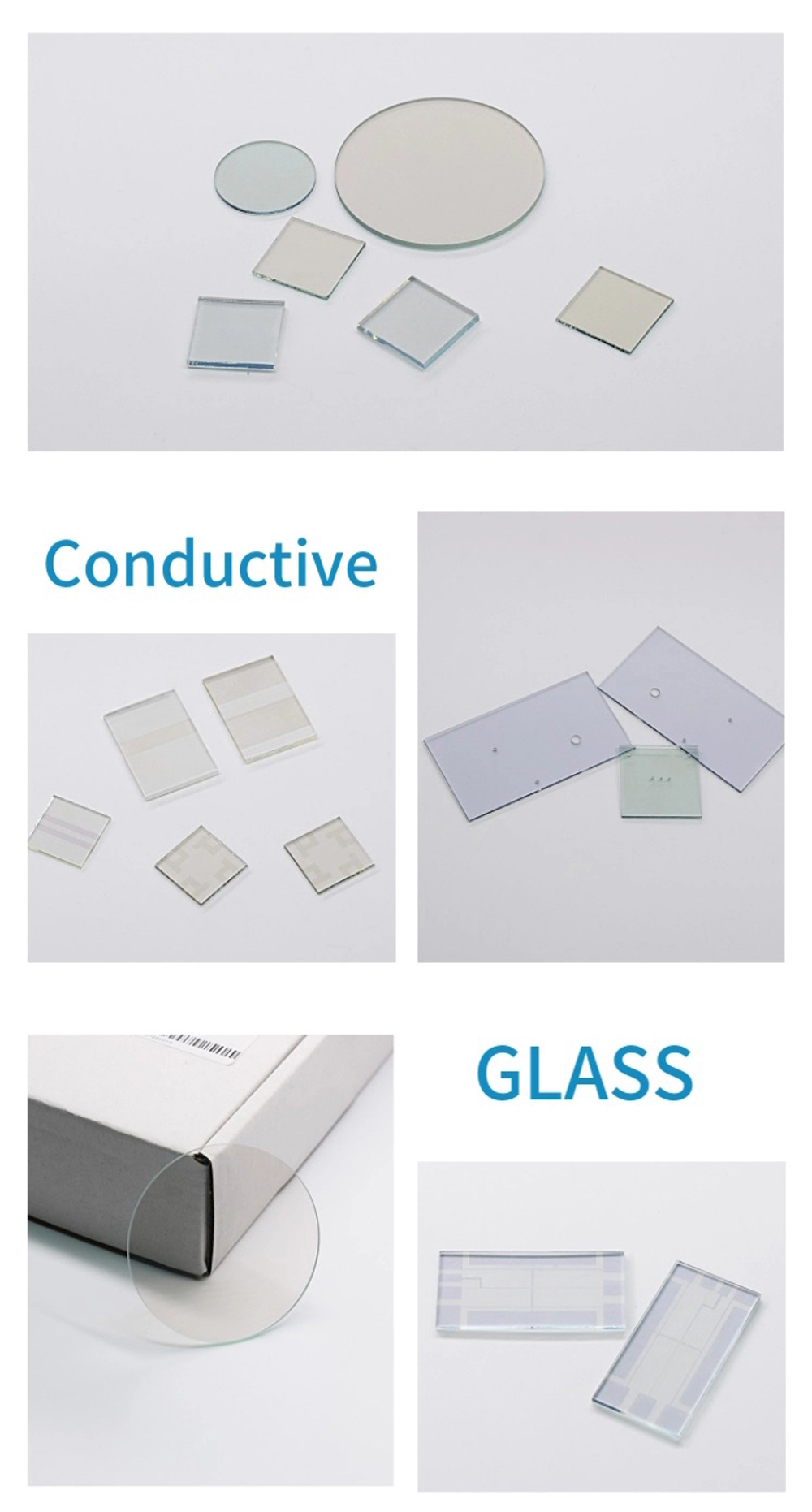

100x100x2.2mm Over 85% Transmission Flourine doped Tin Oxide FTO Glass for Lab. Testing

With good high-temperature performance,600℃, is the best candidate as the transparent conductive electrode material for the dye-sensitized solar cells(DSSC) and the perovskite solar cells application at present.

As a replacement for ITO, it’s widely used in liquid crystal display, photocatalysis, thin film solar cell substrates, dye-sensitized solar cells, electrochromic glass and other fields. Also, FTO glass is a promising touch screen manufacturing technology that realizes the integration of glass and touch.

- ITO/FTO/AZO conductive glass should be stored at room temperature, humidity below 65%, and stored dry;

- the glass should be placed vertically when stored. And conductive glass

- sheets should be separated by a sheet of paper to prevent sodium ions from penetrating into the IT0 conductive layer of the next sheet (see glass structure) ,while preventing the glass sheets from sticking to each other.

2. Cleaning of conductive glass

- During the production, packaging and transportation of conductive glass, the surface of the glass may be contaminated by impurities such as dust and grease.

- The most common cleaning method is ultrasonic cleaning with an organic solvent. Ultrasonic cleaning is generally carried out in the order of:

- toluene → two ethanol → deionized water

- The oil on the surface of the glass is insoluble in water, but it is soluble in organic solvents such as toluene, acetone, and ethanol.

- Among them, toluene has the strongest degreasing ability, so it is first washed with toluene, but toluene cannot remain on the glass surface. Since toluene is soluble in acetone, it can be washed with acetone. Not only can the residual grease be washed away, but toluene is also dissolved.

- Similarly, acetone does not remain on the surface of the glass. Since acetone is easily soluble in ethanol, it can be washed with ethanol.

- Ethanol and water are mutually soluble in any ratio, and finally ethanol is dissolved in a large amount of decompressed water.

FACTORY OVERVIEW

CUSTOMER VISITING & FEEDBACK

All MATERIALS USED ARE COMPLIANT WITH ROHS III (EUROPEAN VERSION), ROHS II (CHINA VERSION), REACH (CURRENT VERSION)

OUR FACTORY

OUR PRODUCTION LINE & WAREHOUSE

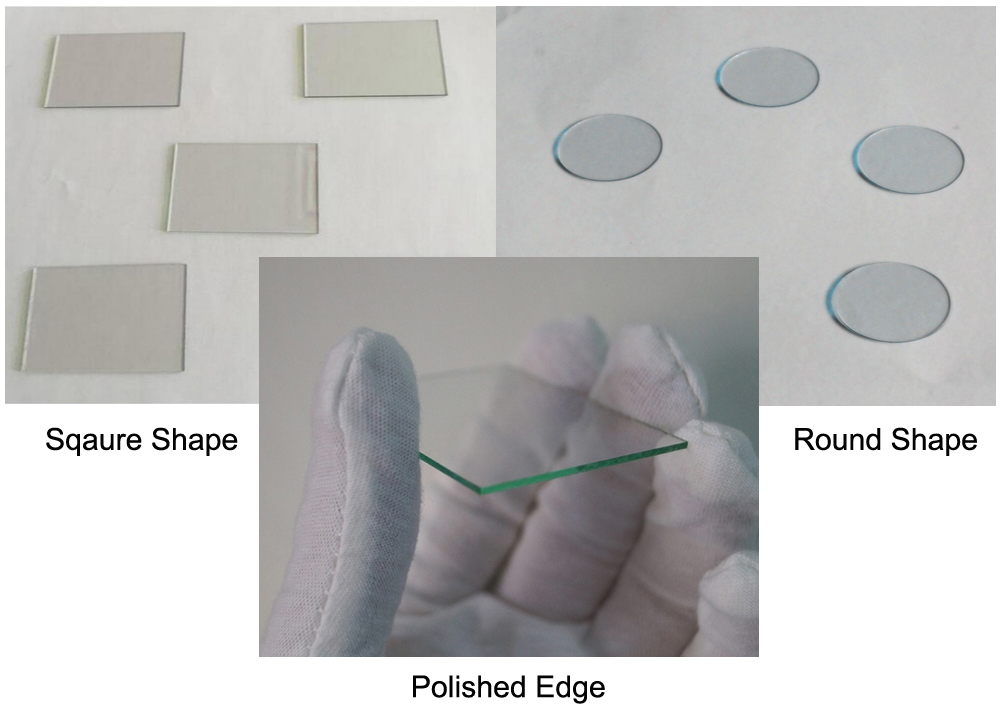

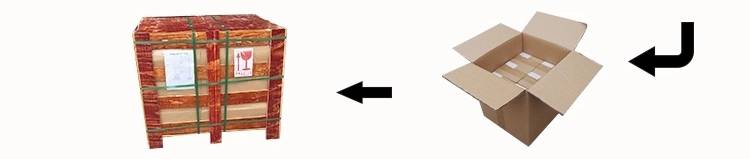

Lamianting protective film — Pearl cotton packing — Kraft paper packing

3 KIND OF WRAPPING CHOICE

Export plywood case pack — Export paper carton pack