FEATURES

- 3.3 Coefficient of Thermal Expansion

- High tembiricha kuramba nemakemikarikugadzikana

-Super scratch inoshingirira & isingapindi mvura & inodzivirira moto

-Yakakwana flatness uye kutsetseka

-vimbiso yenguva yekutumira

-Imwe kune imwe kunyaradza uye kutungamira kwehunyanzvi

-Chimiro, saizi, finsh & dhizaini inogona kugadziriswa sekukumbira

-Anti-glare/Anti-reflective/Anti-fingerprint/Anti-microbial inowanikwa pano

Yakakwira Borosilicate Glass Material Report

| 密度 (Density) | 2.30g/cm² |

| 硬度 (Kuoma) | 6.0' |

| 弹性模量 (Elasticity Modulus) | 67KNmm – 2 |

| 抗张强度(Tensile Strength) | 40 – 120Nmm – 2 |

| 泊松比(Poisson Ratio) | 0.18 |

| 热膨胀系数 (20-400°C) (Coefficient of Thermal Expansion) | (3.3)*10`-6 |

| 导热率比热(90°C)(Specific Heat Conductivity) | 1.2W*(M*K`-1) |

| 折射率 (Refractive Index) | 1.6375 |

| 比热 (Specific Heat) (J/KG) | 830 |

| 熔点 (Melting Point) | 1320°C |

| 软化点 (Softening Point) | 815°C |

| 连续工作温度/使用寿命 (Kuramba Kuchibata Tembiricha/Hupenyu Hwebasa) | 150°C |

| ≥120000h(-60°C-150°C) | 200°C |

| ≥90000h(-60°C-200°C) | 280°C |

| ≥620000h(-60°C-280°C) | 370°C |

| ≥30000h | 520°C |

| ≥130000h | |

| 抗热冲击(Thermal Shock) | ≤350°C |

| 抗冲击强度(Impact Strength) | ≥7J |

| 主要化学成分%含量 (Main Chemical Composition % Content) | |

| SiO2 | 80.40% |

| Fe203 | 0.02% |

| Ti02 | 1.00% |

| B203 | 12.50% |

| Na20+K20 | 4.20% |

| FE | 0.02% |

| 耐水性 (Kushivirira Kwemvura) | HGB 1级 (HGB 1) |

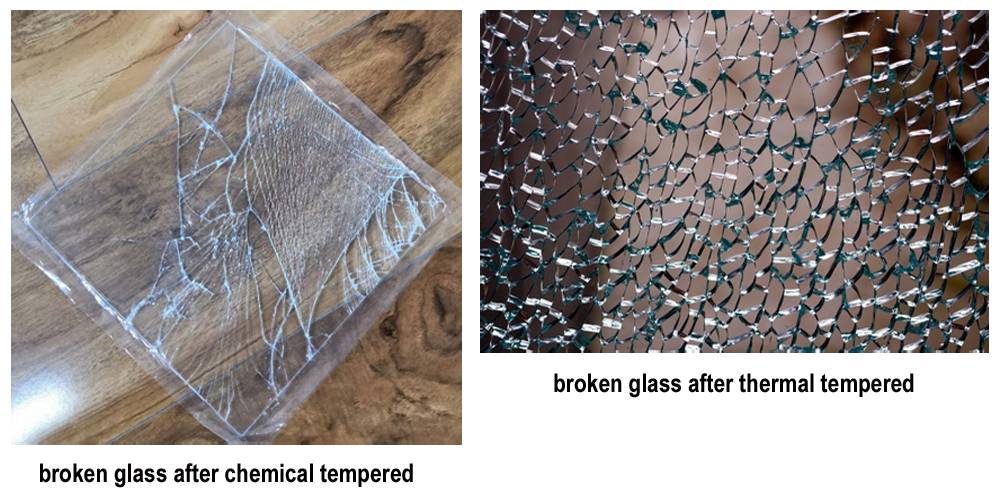

Chii chinonzi kuchengetedza girazi?

Girazi rakapfava kana rakaomeswa imhando yegirazi yekuchengetedza inogadziriswa neinodzorwa yekupisa kana kemikari kurapwa kuwedzera.

kusimba kwaro kana zvichienzaniswa negirazi renguva dzose.

Kupisa kunoisa nzvimbo dzekunze mukutsikirira uye mukati mune makakatanwa.

FACTORY ONGORORO

KUSHANYIRA MUTENGO & FEEDBACK

Zvese ZVINHU ZVINOSHANDISWA NDE ZVINOITWA NEROHS III (EUROPEAN VERSION), ROHS II (CHINA VERSION), SVIKA (CURRENT VERSION)

FEREJI YEDU

YEDU YEKUGADZIRA LINE & WAREHOUSE

Lamianting inodzivirira firimu - Pearl donje kurongedza - Kraft bepa kurongedza

3 RUDZI ROKUPEDZA SARURO

Export plywood kesi paki - Export bepa katoni paki