I-AR enamathela, eyaziwa nangokuthi i-low-reflection coating, inqubo yokwelapha ekhethekile endaweni yengilazi. Umgomo uwukwenza ukucutshungulwa kohlangothi olulodwa noma okukabili endaweni yengilazi ukuze kuyenze ibe nokubukeka okuphansi kunengilazi evamile, nokunciphisa ukubonakaliswa kokukhanya kube ngaphansi kuka-1%. Umthelela wokuphazamiseka okhiqizwe izendlalelo zezinto ezibonakalayo ezihlukene usetshenziselwa ukuqeda ukukhanya kwesigameko nokukhanya okubonisiwe, ngaleyo ndlela kuthuthukiswe ukudluliselwa.

Ingilazi ye-ARikakhulukazi ezisetshenziselwa ukubonisa izikrini zokuvikela idivayisi ezifana nama-LCD TV, ama-PDP TV, amakhompyutha aphathekayo, amakhompuyutha edeskithophu, izikrini zokubonisa ngaphandle, amakhamera, ingilazi yefasitela lasekhishini elibonisa ingilazi, amaphaneli okubonisa amasosha kanye nezinye izingilazi ezisebenzayo.

Izindlela zokugqoka ezivame ukusetshenziswa zihlukaniswe ngezinqubo ze-PVD noma ze-CVD.

I-PVD: I-Physical Vapor Deposition (PVD), eyaziwa nangokuthi ubuchwepheshe bokufakwa komhwamuko obonakalayo, ubuchwepheshe bokulungiselela ukumboza obuncane obusebenzisa izindlela ezibonakalayo ukuze kunciphe futhi kuqongelele izinto ezingaphezulu kwento ngaphansi kwezimo ze-vacuum. Lobu buchwepheshe bokumboza buhlukaniswe ikakhulukazi ngezinhlobo ezintathu: i-vacuum sputtering coating, i-vacuum ion plating, kanye ne-vacuum evaporation coating. Ingakwazi ukuhlangabezana nezidingo zokumboza zama-substrates afaka amapulasitiki, ingilazi, izinsimbi, amafilimu, izitsha zobumba, njll.

I-CVD: I-Chemical Vapor Evaporation (CVD) ibizwa nangokuthi i-chemical vapor deposition, okubhekisela ekuphenduleni kwesigaba segesi ekushiseni okuphezulu, ukubola okushisayo kwe-metal halide, izinsimbi eziphilayo, ama-hydrocarbons, njll., ukuncishiswa kwe-hydrogen noma indlela yokubangela igesi yayo exubekile ukuba isabele ngamakhemikhali ekushiseni okuphezulu ukuze kuncishiswe izinto ze-inorganic oxide, izinsimbi, ne-carbioxide. Isetshenziswa kabanzi ekukhiqizeni izendlalelo zezinto ezikwazi ukumelana nokushisa, izinsimbi ezihlanzekile kakhulu, namafilimu amancanyana e-semiconductor.

Isakhiwo sokumboza:

A. I-AR yohlangothi olulodwa (ungqimba olukabili) IGLASS\TIO2\SIO2

B. I-AR enezinhlangothi ezimbili (izendlalelo ezine) SIO2\TIO2\GLASS\TIO2\SIO2

C. Multi-layer AR (ukwenza ngokwezifiso ngokwezidingo zekhasimende)

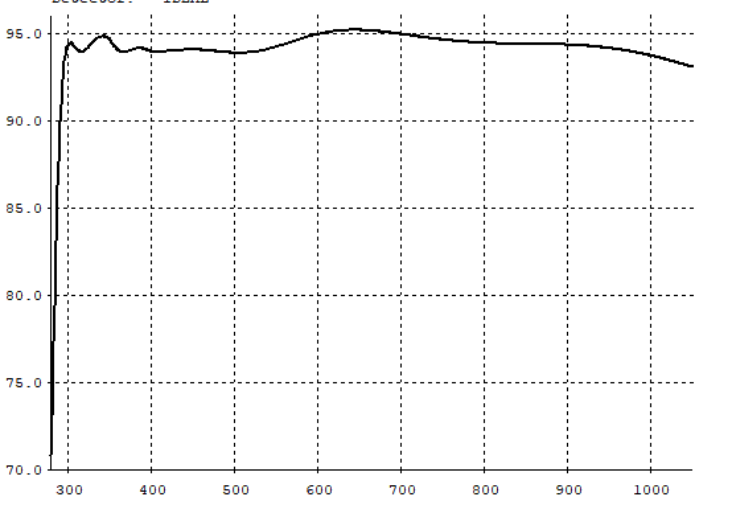

D. I-transmittance inyusiwe isuka cishe ku-88% yengilazi evamile iye ngaphezu kwama-95% (kufika ku-99.5%, okubuye kuhlotshaniswe nokuqina nokukhethwa kwezinto ezibonakalayo).

E. Ukukhanya kuncishisiwe kusuka ku-8% wengilazi evamile kuya ngaphansi kuka-2% (kufika ku-0.2%), kunciphisa ngempumelelo isici sokwenza mhlophe isithombe ngenxa yokukhanya okuqinile okuvela ngemuva, nokujabulela ikhwalithi yesithombe ecace kakhudlwana.

F. I-Ultraviolet spectrum transmittance

G. Ukumelana nokuklwebheka okuhle kakhulu, ubulukhuni >= 7H

H. Ukumelana nemvelo okuhle kakhulu, ngemuva kokumelana ne-asidi, ukumelana ne-alkali, ukumelana ne-solvent, umjikelezo wezinga lokushisa, izinga lokushisa eliphezulu nezinye izivivinyo, isendlalelo sokumboza asinazo izinguquko ezisobala.

I. Ukucaciswa kokucubungula: 1200mm x1700mm ukujiya: 1.1mm-12mm

I-transmittance iyathuthukiswa, ngokuvamile ebangeni lebhendi yokukhanya ebonakalayo. Ngokungeziwe ku-380-780nm, Inkampani ye-Saida Glass ingakwazi futhi ukwenza ngokwezifiso ukudluliselwa okuphezulu ebangeni le-Ultraviolet kanye nokudluliswa okuphezulu ebangeni le-Infrared ukuze kuhlangatshezwane nezidingo zakho ezihlukahlukene. Siyakwamukela kuthumela imibuzoukuze uthole impendulo esheshayo.

Isikhathi sokuthumela: Jul-18-2024